Our Process

After ties have been removed from the ground, we load and transport them to one of our facilities located across the United States. There they are processed – sorted, graded, bundled, and banded. Through a defined quality control process, we apply consistent grading standards across our facilities.

Common Standard Railroad Tie Types

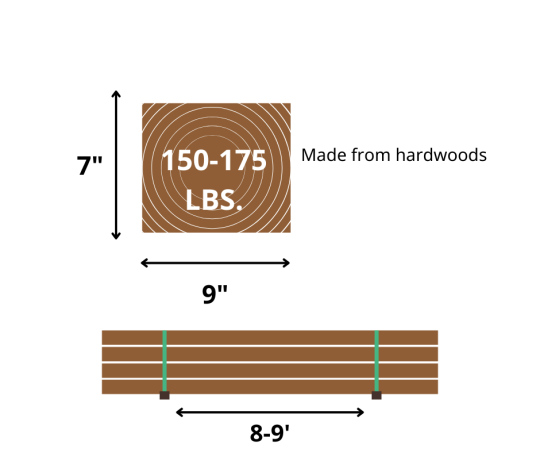

Used Railroad Tie

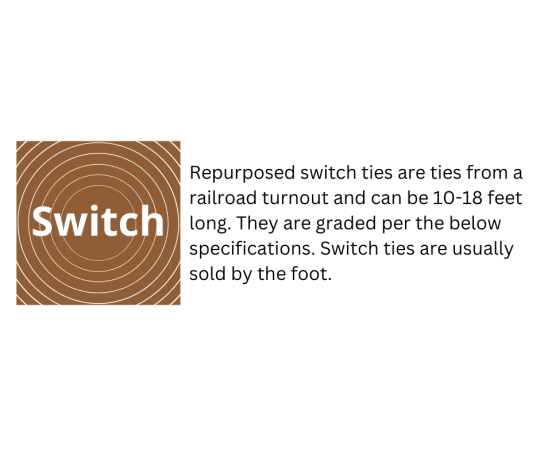

Switch Tie

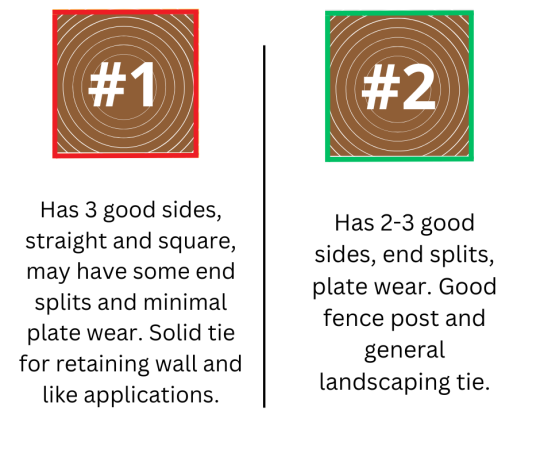

Omaha Track Tie Grading Standards

ADDED SERVICES

Signature Banding

- Ties are banded with high strength recyclable poly bands on each end.

- Bands are custom made for Omaha Track for safety and effectiveness.

- Wood runners are aligned to the bottom of each bundle for safe offloading.

Delivery Options

- Our tie delivery to retail stores via flatbed trucks is competitively priced.

- We use centerbeam rail cars for cross-country delivery.